Tel: 400 6622 333

Detailed content

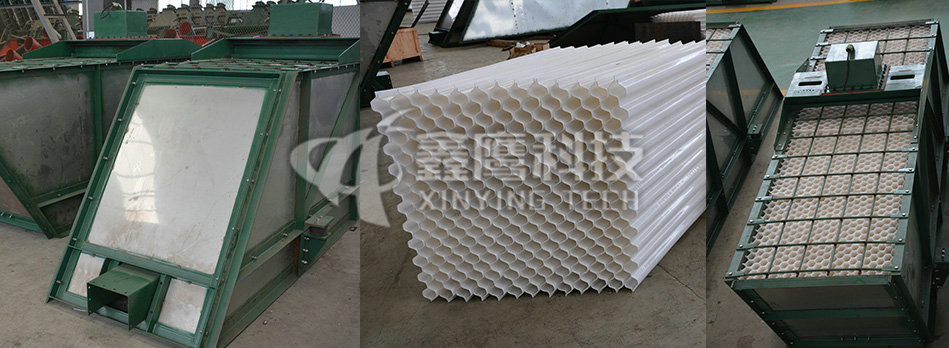

Designed with the theory of shallow settlement and deep filtration of dispersed particles, GXN anti-clogging high-efficiency inclined tube thickener is a newly developed sedimentation treatment equipment that integrates multi-layer and multi-grid, counter current feeding and plate precipitation techniques. As the bottom of the hopper is installed with a barrier-free draining device, it is advantageous to control grit concentration and avoid congestion in the sand outlet.

Features

1. The inclined tube has a large effective sedimentation area and the settling time of solid particles is short covering small sedimentation distance. With efficient concentration and classification, its handling capacity per unit is large, generally 4-10 times larger than the average. It takes less space, about 1/3 of the ordinary thickener or 80% of the high efficiency inclined plate thickener. The outlet can discharge the ore pulp of high concentrations, which is higher than 70% (mass concentration).

2. It is anti-static and abrasion resistant. The inclined tube is processed with special polymer material features smooth and hydrophobic surface. The tube surface do not contains slime.

3. A modular design: large equipment can be assembled by combining and integrating multiple modules in a series and parallel arrangement. The installation and maintenance are convenient and the operation is stable and reliable.

4. The inclined tube modules are intermittent vibrated with high frequency automatically cleaning up the inclined tube’s surface. Because no material piles up on its surface, its channels will never be congested.

5. The effective sedimentation area of inclined tubes per unit flat area is two times larger than that of the inclined plates.

6. The equipment can be used either for concentration and returning water or for classification and desliming. Adding flocculant to pulp as a way of pretreatment can also be applied as the high-efficiency thickener.

7. It has the advantages of small space occupation, low power consumption, low cost for use and maintenance.

8. Enjoying a compact structure, it is convenient to install and use the equipment that can operate in a stable manner. And it saves energy and water. Little investment in the equipment should lead to quick returns.

Specification & Model

The equipment has three types of inclined tubes and a variety of 17 models of different specifications with a nominal area of 32-2500m2,equivalent to an average circular thickener of 6-53m in diameter. Customers can choose one based on demand.

Model GXN-1200/55-nominal area 1200m2/inclined tube tilt angle 55°, pedestal support height 1.8m

|

Model

|

Occupied Area (m2)

|

Hopper Number

|

L×W×H (m)

|

Equivalent to Diameter of common Thickeners (m)

|

|

GXN-32/55

|

4.5

|

1

|

3.69×1.2×4.36

|

6

|

|

GXN-64/55

|

9

|

1

|

3.69×2.46×4.36

|

9

|

|

GXN-100/55

|

13.6

|

1

|

5.56×2.46×5.63

|

10.5

|

|

GXN-125/55

|

20

|

1

|

5.56×3.56×5.5

|

12

|

|

GXN-150/55

|

24

|

1

|

5.54×4.68×8.15

|

13

|

|

GXN-200/55

|

26.5

|

1

|

5.98×5.54×8.15

|

15

|

|

GXN-250/55

|

35

|

1

|

7.16×4.8×6.6

|

16.6

|

|

GXN-300/55

|

42

|

1

|

7.16×5.9×6.8

|

18

|

|

GXN-400/55

|

66

|

2

|

11.09×4.68×8.15

|

21

|

|

GXN-500/55

|

69

|

2

|

11.09×5.98×8.15

|

24

|

|

GXN-600/55

|

80

|

2

|

11.09×4.68×8.15

|

26

|

|

GXN-800/55

|

100

|

4

|

7.09×11.3×8.5

|

30

|

|

GXN-1000/55

|

130

|

4

|

14.64×6.86×8.2

|

33

|

|

GXN-1200/55

|

160

|

4

|

11.09×11.09×9.71

|

36

|

|

GXN-1500/55

|

189

|

4

|

14.35×11.18×8.5

|

41

|

|

GXN-2000/55

|

263

|

8

|

22.53×11.09×9.71

|

48

|

|

GXN-2500/55

|

321

|

8

|

22.47×11.36×10.43

|

53

|

Package product

Related Projects

Order

Contact us

Add: Non-ferrous Industry Zone, Huangjin shan Economy Development District, Huangshi City, Hubei Province, China

Tel: 0086-714-3268866

Fax: 0086-714-3268800

Http://www.xinyingtec.com

www.xinyingkeji.com

E-mail: xinyintec@163.com

907916039@qq.com

GXN Vibration Anti-Clogging High Frequency Inclined Tube Thickener

GXN Vibration Anti-Clogging High Frequency Inclined Tube Thickener