Tel: 400 6622 333

Detailed content

Patent No.: ZL201721243555.4

Brief introduction

Superimposed high frequency vibrating screen is a kind of superfine screen, which is mainly suitable for material classification from 0.043mm to 1mm. It is an ideal substitute for hydrocyclone because it can provide greater processing capacity and classification efficiency. The ultra-fine sieving machine solves all the challenges of the previous fine wet sieving technology and enables our customers to apply this technology extensively to achieve high grinding separation efficiency for the purpose of improving their economic benefits.

Design features

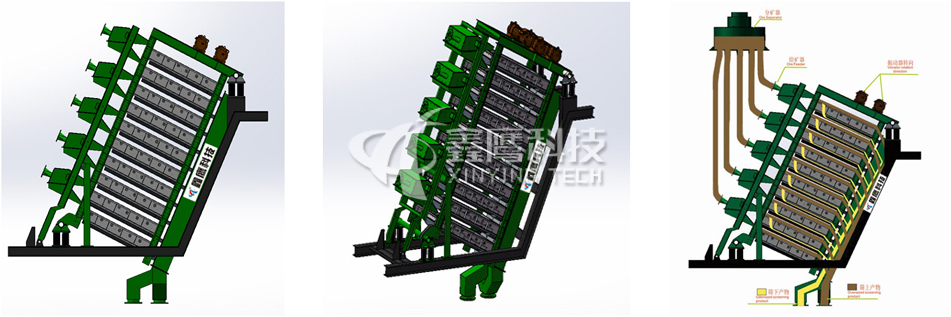

Modular design is adopted for the high frequency double-layer vibrating screen, and the multi-layer screen frame is integrated into a whole. Up to 10 separate screen frames can be embedded in a single whole assembly. For this super fine screen, the accurate separation of the ore feeding is of vital importance. Therefore, a new slurry distribution system is used to ensure the uniform distribution of materials on each layer of screen.

Main advantages

1. Larger screen area

The ten-layer double-layer high frequency vibrating screen is composed of 10-layer screen frame, and each screen frame is arranged with two screens, a total of 20 screens, so the screening area is twice that of the original five-layer high frequency vibrating screen.

2. Small space cover

The ten-layer double-layer high frequency vibrating screen adopts a rather compact overall arrangement, which has twice the screening area compared with the five-layer high frequency vibrating screen, and the equipment covers a small area.

3. Save on infrastructure costs

As a result of the smaller space cover, one ten-layer double-layer high frequency vibrating screen replaces two five-layer high frequency vibrating screens, the infrastructure construction is reduced by half, the layout of the slurry pipeline is reduced by half, and the intensity of field management and manual maintenance can also be reduced.

4. Vibrator optimization

The vibrating body is made up of 10 layers of stainless steel, which greatly reduces the vibration weight and further optimizes the vibration.

5. Damping optimization

The five-layer high frequency vibration screen adopts side suspension spring with large shear force. The ten-layer double high frequency vibration screen breaks the original shock absorption mode and adopts vertical support compound spring.

6. Low energy consumption

By reducing the vibration weight and optimizing the shock absorption, the energy consumption of the ten-layer double-layer high frequency vibrating screen was greatly reduced. The energy consumption of the original two five-layer high frequency vibrating screens was 2*4.5kw, and the energy consumption of the sieve was 2*3.7kw, which was more energy-saving and environmentally friendly.

7. General interchangeable accessories

In addition to the ore feeder, other accessories of ten-layer double-layer high frequency vibrating screen have good general interchangeability with five-layer high frequency vibrating screen.

8. Higher screening quality efficiency

A ten-layer double-layer high frequency vibrating screen has a processing capacity of 1.7~1.9 times of a five-layer high frequency vibrating screen. Under the same sieve component efficiency, the mass efficiency of the ten-layer double-layer high frequency vibrating screen can increase by about 5%.

9. Good applicability

Compared with the five-layer double-layer high-frequency vibrating screen, the ten-layer double-layer high-frequency vibrating screen is only 1.2m in height and 0.2m in width, but its length is smaller. If the height is appropriate, 1 double-layer high frequency vibrating screen can be installed on the area of the original 5 layers. If the height is not enough, it is recommended to use 8-layer double-layer high frequency vibrating screen, which is the same as the installation size of five-layer screen, but has a screen area of 1.6 times. The superimposed high frequency vibrating screen is suitable for the newly built and technological upgrading plant, which has good applicability.

Technical indicator

| Model | XYFVS-10-1007 | XYFVS-8-1007 | XYFVS-6-1007 | XYFVS-4-1007 | XYFVS-2-1007 | |

| Screen frame number | 10 | 8 | 6 | 4 | 2 | |

| Screening area(m2) | 15 | 12 | 9 | 6 | 3 | |

| The motor power(HP) | 2*3.8 | 2*2.25 | ||||

| Speed (rpm) | 1500至2900 | |||||

| The amplitude(mm) | 0.5~2.6 | |||||

| Sieve machine overall width(m) | 1.880 | |||||

| Total length of sieve machine(m) | 5.818 | 5.5 | 5.2 | 4.9 | 4.6 | |

| Sieve machine total height (m) | 5.635 | 4.925 | 4.211 | 3.497 | 2.773 | |

| Mesh size (mm) | 0.043,0.054,0.063,0.075,0.100,0.120,0.150,0.180,0.220,0.30,0.430,1.0 | |||||

Package product

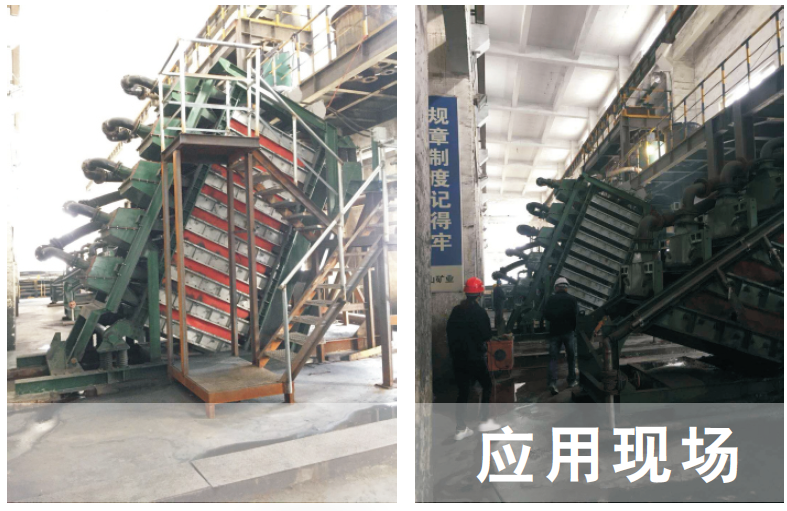

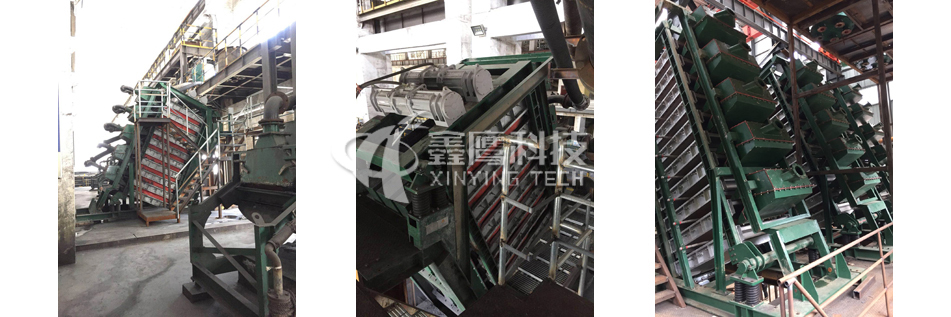

Related Projects

Order

Contact us

Add: Non-ferrous Industry Zone, Huangjin shan Economy Development District, Huangshi City, Hubei Province, China

Tel: 0086-714-3268866

Fax: 0086-714-3268800

Http://www.xinyingtec.com

www.xinyingkeji.com

E-mail: xinyintec@163.com

907916039@qq.com

XYFVS superimposed high frequency vibrating screen (ten laminated)

XYFVS superimposed high frequency vibrating screen (ten laminated)