Tel: 400 6622 333

Detailed content

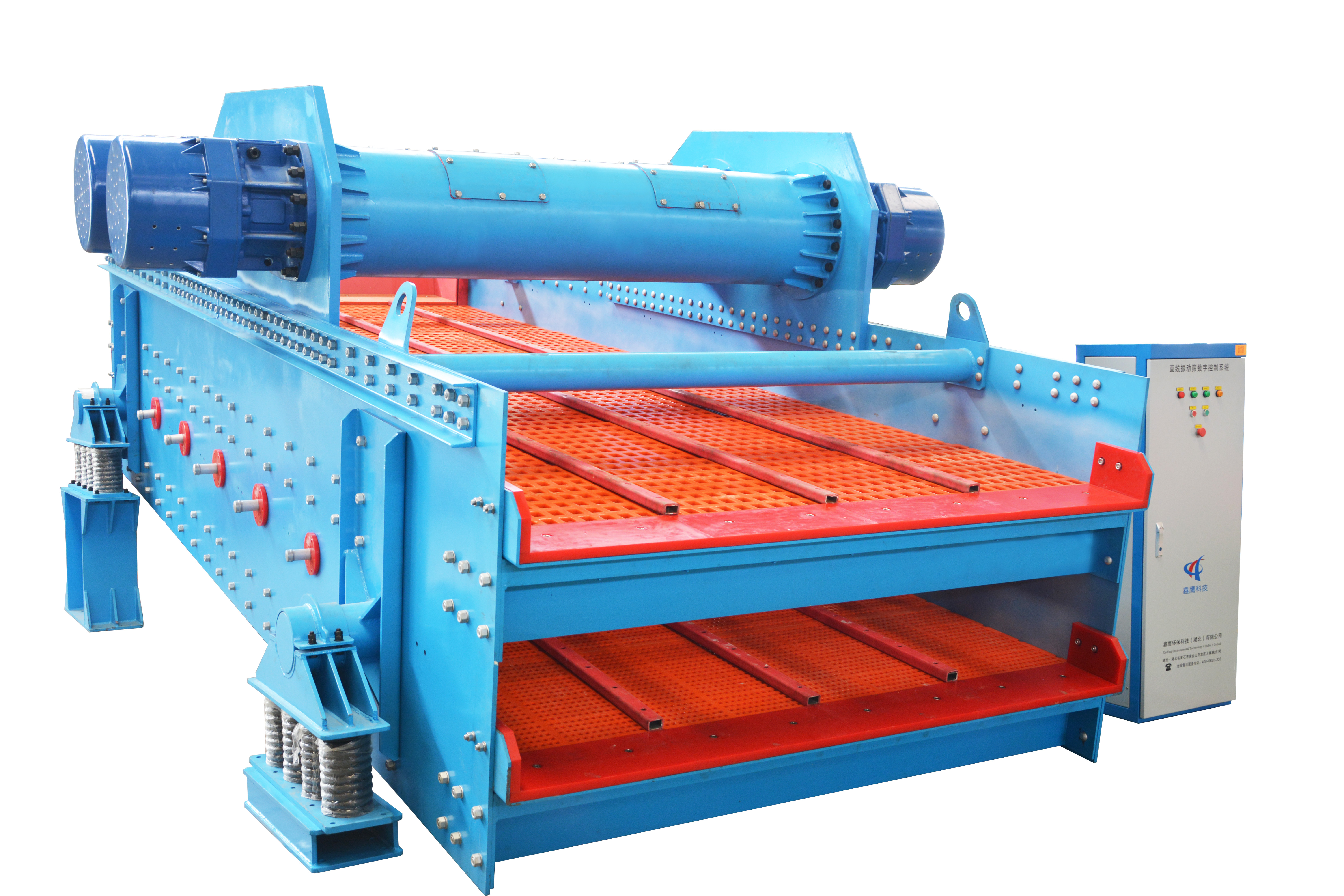

MLF series medium frequency linear vibrating screen

MLF series medium frequency linear vibrating screen is a high-efficiency screen machine independently developed by our company. On the basis of absorbing the advantages of similar vibrating screens at home and abroad, this screen machine is a new type of high-efficiency vibrating screen machine successfully developed in combination with our company's research experience in the use of high-frequency vibrating fine screen and market demand. The new maintenance free electric vibrator (flange type electric vibrator) is used to replace the traditional block eccentric vibrator, The excitation mode is more simple and reliable, and the maintenance workload is reduced; It has the advantages of high screening efficiency, large treatment capacity, low installation space, convenient maintenance and low production cost. It is suitable for screening, medium removal, dehydration and desliming in nonferrous metals, metallurgy and coal industries.

characteristic

1. MLF linear vibrating screen can run in oval and linear stroke. Linear stroke and elliptical stroke realize horizontal installation or small inclination (- 5-5 °), which can effectively reduce the height of civil engineering and save installation space.

2. MLF linear vibrating screen has a wide range of stroke, and the exciting force produced by two unbalance blocks can reach 6-6.5g.

3. Using maintenance free flange electric vibrator, the maintenance workload of vibrator is very little.

4. The flange electric vibrator is installed on the side plate of the screening machine, so the maintenance of the motor is convenient.

5. After the screen frame is assembled as a whole, the machine base mounting holes on both sides of the screen frame are bored once on the large floor CNC milling and boring machine, which ensures the concentricity requirements of the mounting holes of the two vibration motors. Avoid the phenomenon that the two vibrating motors are not concentric, causing the bearing sleeve to burn out and the screen machine to swing.

6. Through flexible connection, the two flange vibration motors can realize synchronous transmission and reduce the impact on the motor.

7. The support of screen machine adopts shock absorption spring, which has the advantages of long service life, corrosion resistance, stable passing through resonance area, low noise and small impact on foundation.

8. Large processing capacity of screening machine: the screening machine has single-layer screen, double-layer screen and three-layer screen, with wide particle size range and screening area of 3-29m2. At the same time, it adopts anti blocking and wear-resistant polyurethane screen, with large processing capacity, which can be selected according to the size of working conditions.

9. Linear / elliptical stroke.

10. Modular design.

11. Good adjustability

12. Flexible configuration.

13. It is easy to maintain and has low operation cost.

|

Model type |

size |

weight (t) |

||

|

mm(W* L) |

Single-deck

|

Double-decks |

Three-decks |

|

|

MLF-1230 |

1240X3000 |

1.9 |

3.3 |

|

|

MLF-1245 |

1240X4500 |

2.8 |

4.9 |

|

|

MLF-1845 |

1850X4500 |

4.2 |

7.3 |

|

|

MLF-1852 |

1850X5250 |

4.9 |

8.5 |

|

|

MLF-1860 |

1850X6000 |

5.6 |

9.8 |

12.8 |

|

MLF-2452 |

2460X5252 |

6.5 |

11.4 |

|

|

MLF-2460 |

2460X6000 |

7.5 |

13.0 |

17.0 |

|

MLF-2475 |

2460X7500 |

9.3 |

16.3 |

21.3 |

|

MLF-3060 |

3070X6000 |

9.3 |

16.3 |

21.3 |

|

MLF-3075 |

3070X7500 |

11.7 |

20.3 |

26.6 |

|

MLF-3660 |

3680X6000 |

11.2 |

19.5 |

25.5 |

|

MLF-3675 |

3680X7500 |

14.0 |

24.4 |

31.9 |

|

MLF-4282 |

4290X8250 |

|

31.3 |

|

|

MLF-4297 |

4290X9750 |

|

37.0 |

|

|

Note: All screen aperture are 0.5-50mm. Processing quantity of screen machine is determined according to material nature and aperture. |

||||

Package product

Related Projects

Order

Contact us

Add: Non-ferrous Industry Zone, Huangjin shan Economy Development District, Huangshi City, Hubei Province, China

Tel: 0086-714-3268866

Fax: 0086-714-3268800

Http://www.xinyingtec.com

www.xinyingkeji.com

E-mail: xinyintec@163.com

907916039@qq.com

MLF series medium frequency linear vibrating screen

MLF series medium frequency linear vibrating screen