Tel: 400 6622 333

Detailed content

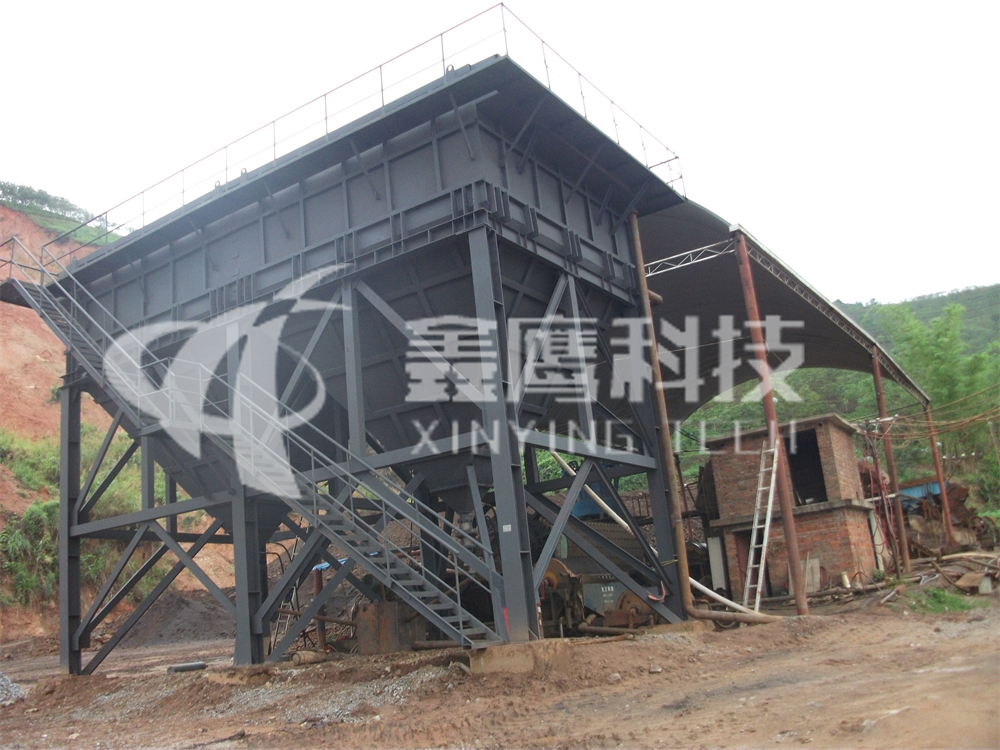

BGXN high frequency vibrating tilt plate thickener

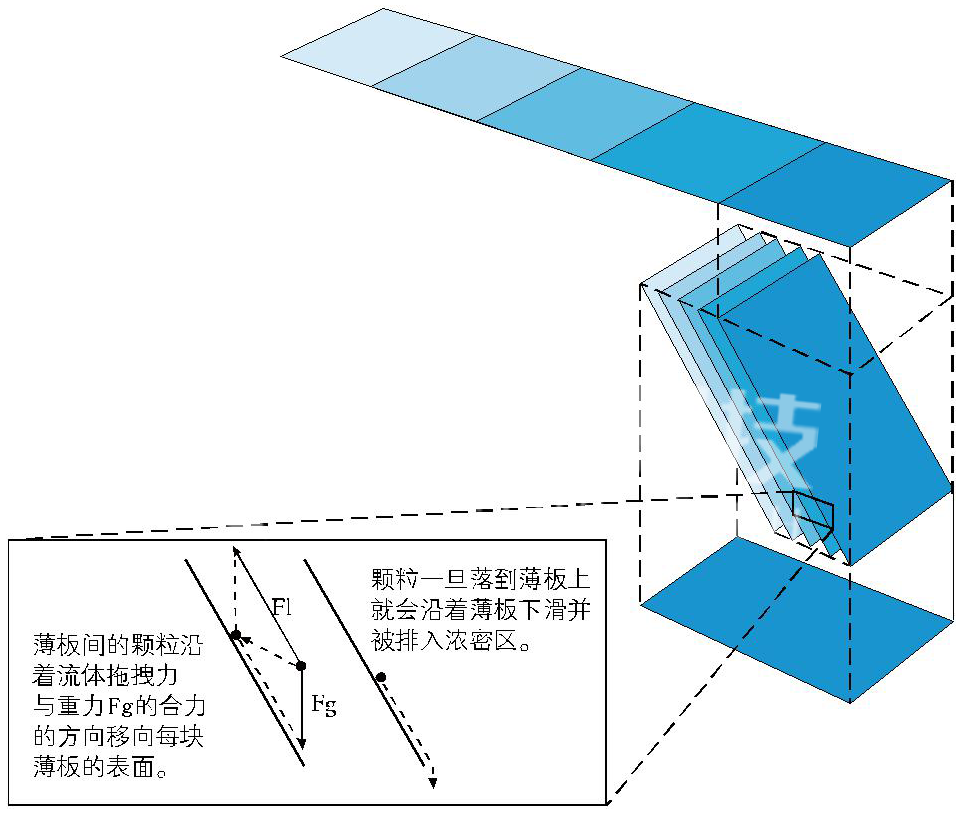

The principle of xinying BGXN high frequency vibrating inclined plate thickener is to maximize the settlement area over the available bottom area by using parallel inclined plates.Thus, clarification requirements can be better matched with thickening requirements in this way, thus minimizing the size and cost of gravity settling equipment.

Two basic standards for gravity settling equipmentThat is: the clarity of the overflow liquid is better, the bottomThe flow discharges the solid density to the maximum.The area required for suspension clarification is oftenMuch larger than the area required to be dense. It'sWhich means that in a cylindrical dense tank, the bottom is loadedThe rake and drive parts can be largeThe size of the.Thin plate principle is the use of several sets of parallel inclined plateThe settlement area on any available base area reaches the maximumBig. Therefore, clarification can be made by means of the thin plate principleThe requirements match better with the thickening requirements, thus putting the weightReduction in size and cost of force settling equipmentThe lowest.

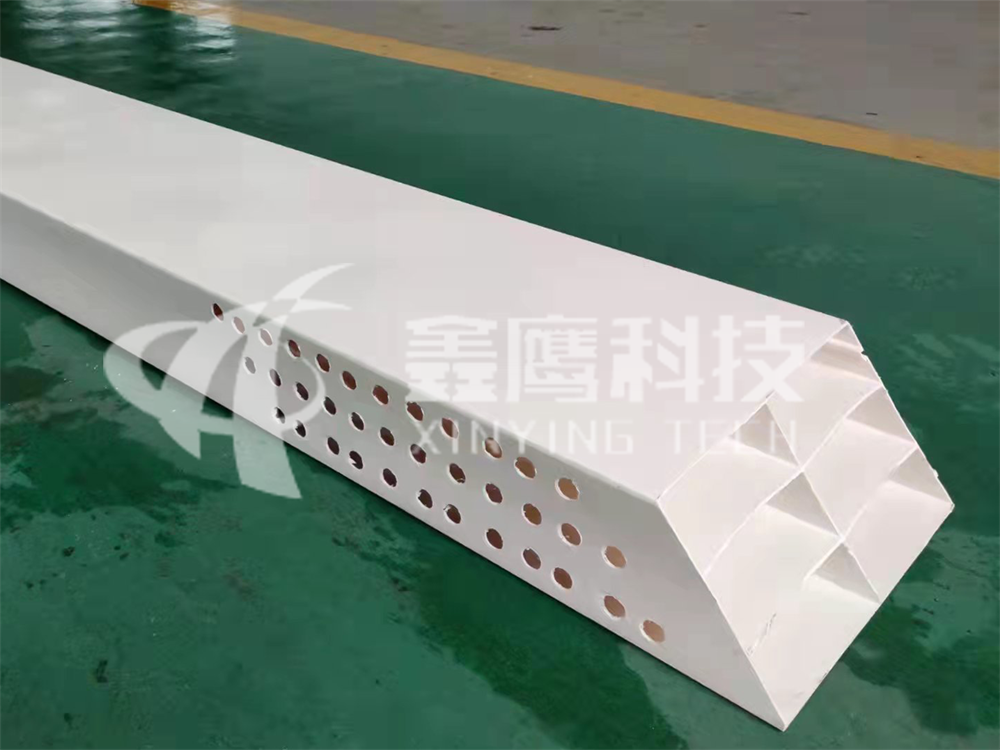

The inclined plate group module can automatically clean the inclined plate surface by intermittent intelligent high-frequency vibration. The inclined plate surface can accumulate materials and the channel will never be blocked.

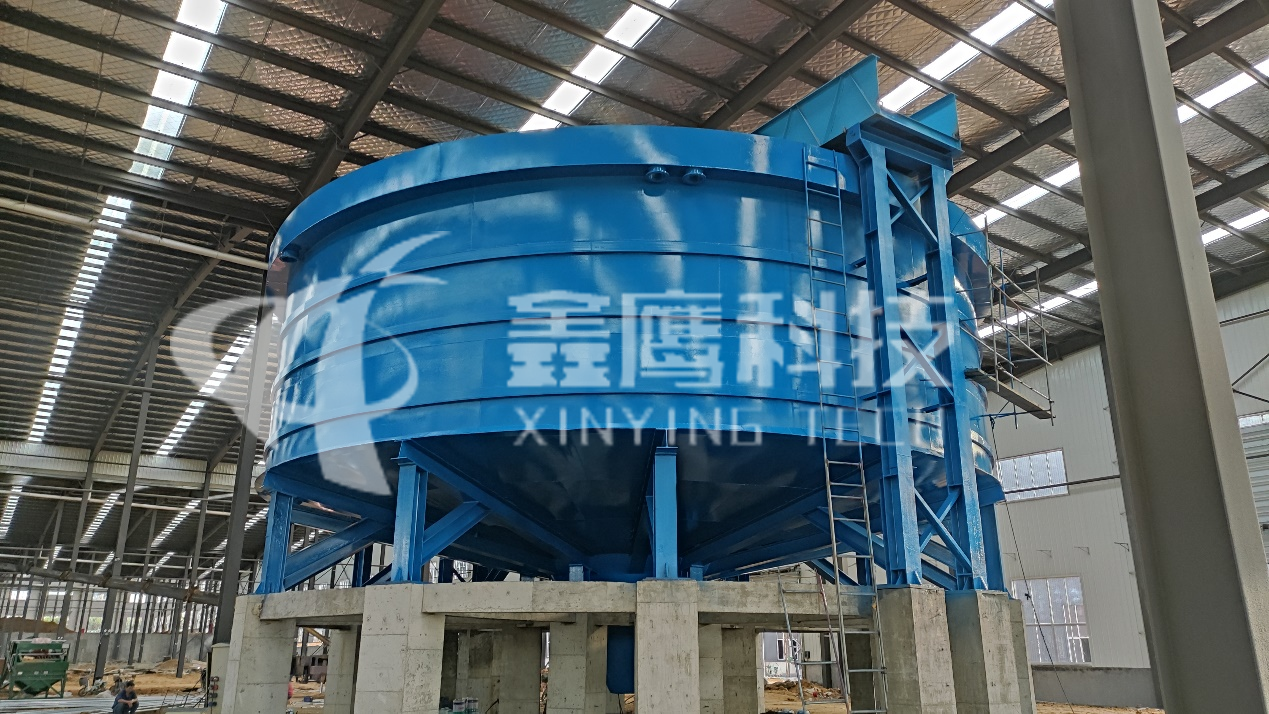

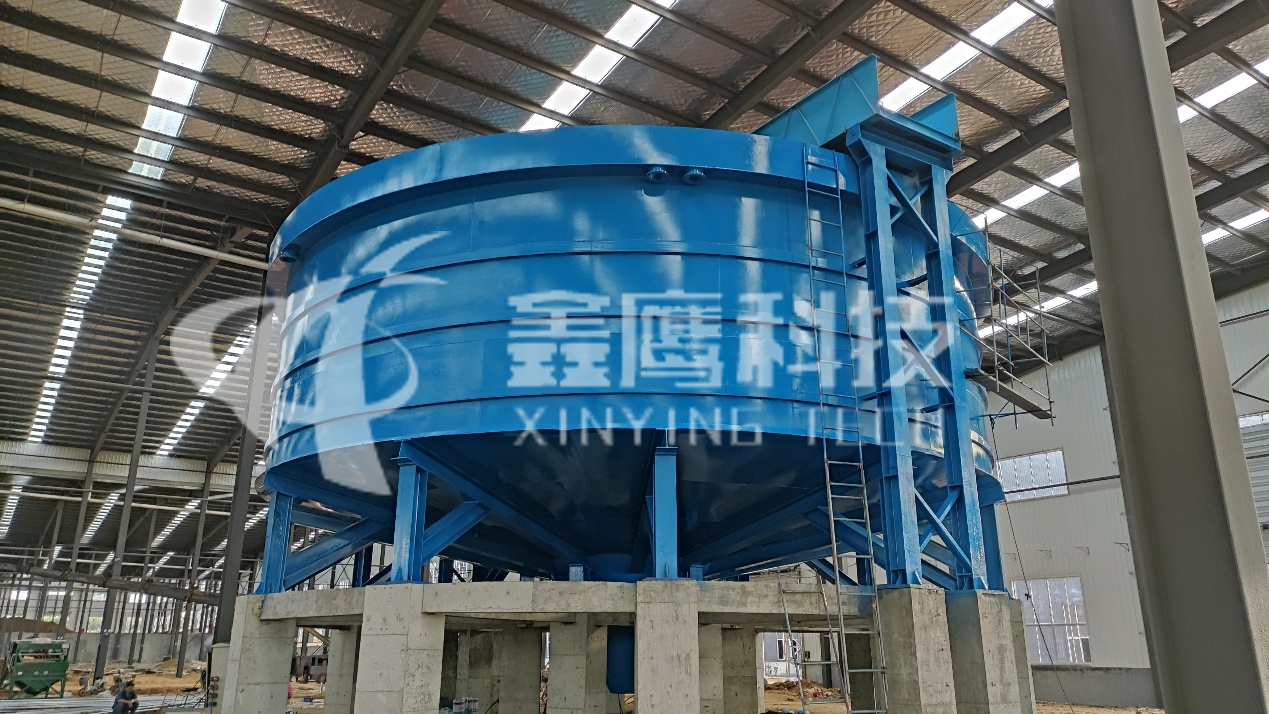

BGXN high frequency vibration tilt plate thickener is mainly composed of two upper and lower layers including the box body 50-55° of the inclined inclined plate, the bottom is a column type slime bucket.

The pulp enters the thickener vertically from one side of the upper box body, and then enters the gap of the high-frequency vibration inclined plate through the trough entrance. The slurry is clarified in a high-frequency vibrating inclined plate above the inlet position so that the clarification fluid does not mix with the incoming slurry.

Each group of high-frequency vibration inclined plate is provided with a full-length overflow groove above, and a throttle hole at the bottom of the groove, so as to create hydraulic back pressure of the feed flow. This feeding control method can ensure that the pulp enters evenly into each plate settling chamber, and can minimize the pulp turbulence at the feed port.

Solid particles first settle on the high-frequency vibration inclined plate, and then slide along the high-frequency vibration inclined plate to the slime hopper, and then use the rake system to further concentrate the solid particles in the slime hopper.

advantages

Box body, slime bucket, high-frequency vibration inclined plate group and rake are all heavy equipment, and rake lifting mechanism is selected

The ratio of clarification area to concentration area can be optimized by specially designed feeding location

No slurry short circuit or surface turbulence phenomenon

Low installation cost

Delivered as a whole or prefabricated component

The basic size of the equipment is small

Small footprint

Small internal volume and surface area

Easy to insulate or prevent toxic fumes

Minimum evaporation loss

Simple steel plate and standard configuration construction

Special materials and coating, easy to combine

Convenient maintenance

Convenient site installation

Short line

High position installation, easy to downstream process gravity feeding

Easy to regulation

High adaptability to plant renovation or expansion

Can be installed in any system

Easy to reposition, suitable for technological transformation

BGXN high frequency vibrating inclined plate thickener consists of a number of high frequency vibrating inclined plate boxes installed in a conventional cylindrical thickening tank, using a standard center drive rake device to discharge dense slime.

The compact precast inclined plate box with high frequency vibration enables the BGXN thickener to clear a large area, while taking up a fraction of the floor space of a conventional inclined plate box thickener without high frequency vibration.

The BGXN thickening system significantly reduces the cost of investment in equipment.

For some applications, the BGXN thickener can be used as a clarifier, and the clarifier sorting point can be changed by changing the number of high-frequency vibrating tilt plate boxes.

BGXN high-frequency vibrating tilt panel boxes can also be installed in existing dense or clarification tanks to increase the available clarification area, or rectangular clarification tanks can be used to increase the clarification area.

BGXN thickener is specially modified to achieve higher concentration rate and slime buffering capacity.

The core of the BGXN system is the use of high-frequency vibration tilting plate box to minimize the floor area of the thickener and maximize the clarification area, which can be used to minimize the amount of flocculant or no flocculant.

Package product

Related Projects

Order

Contact us

Add: Non-ferrous Industry Zone, Huangjin shan Economy Development District, Huangshi City, Hubei Province, China

Tel: 0086-714-3268866

Fax: 0086-714-3268800

Http://www.xinyingtec.com

www.xinyingkeji.com

E-mail: xinyintec@163.com

907916039@qq.com

BGXN high frequency vibrating tilt plate thickener

BGXN high frequency vibrating tilt plate thickener