Tel: 400 6622 333

Detailed content

Year 2002: TPU thermoplastic polyester screenswere developed;

Year 2002: TPU thermoplastic polyester screenswere developed;

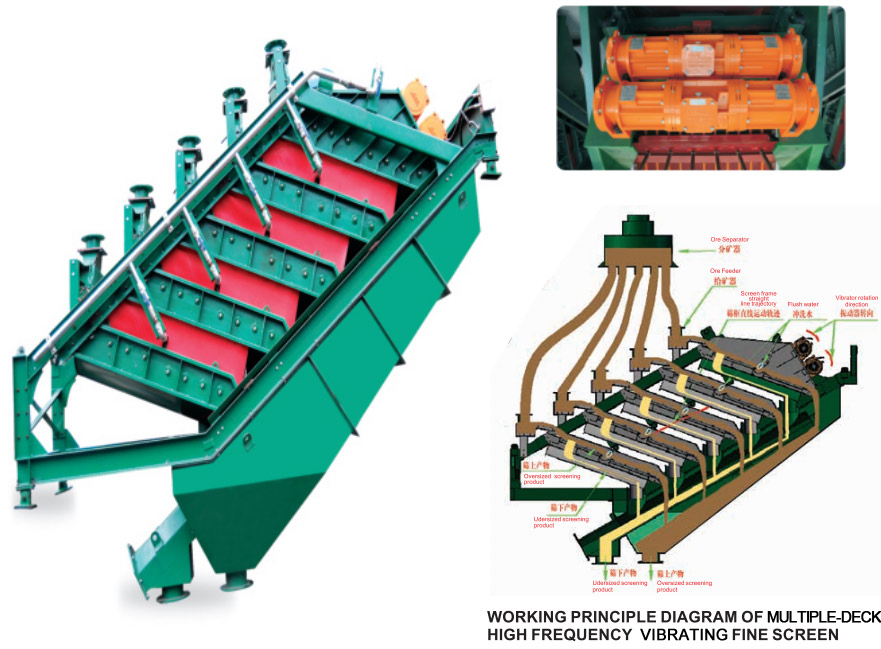

Year 2003: development of multiple-deck high-frequency vibrating fine screen was initiated;

Year 2004: the CPU casting polyester screens were developed and put into production; the first three-deck high-frequency vibrating fine screen powered by domestically-made a long cylindrical electric vibrator was developed;

Year 2005: the three-deck high-frequency vibrating fine screens were put into production and the five-deck high-frequency vibrating fine screens were successfully developed;

Year 2006: the five-deck high-frequency vibrating fine screens were put into production 0.20 mm polyester screens were successfully developed;

Year 2007: the long-cylinder electric vibrator and wear-resistant glue spraying technology imported were applied in iron ore industry;

Year 2008: 0.10 mm polyester screens were developed;

Year 2009: 0.08mm polyester screens were developed;

Year 2010: the frequency conversion multiple-deck high-frequency vibrating fine screens were developed and put into production;

Year 2011: the linear dewatering vibrating screens were developed and put into production

Year 2012: three patents on high-frequency vibrating screens and four on vertical ring pulsating high gradient magnetic separator was approved

Main features & Advantages

1.Large processing capacity with over 80% of screening efficiency

2.With multiple decks parallel connection and occupying small space, it can achieve the maximum of five decks parallel connection.

3.Thanks to the screen frame supported by rubber springs, it produces lower noise and consumes less power with low dynamic load, thus making no special requirement for the installing base.

4.The utilization of ore pulp distribution method makes it possible to slow down the pulp flow rate and extend the service life of screen; The method allows the pulp to be evenly spread on the screen surface, which is quite helpful to improve the efficiency of processing and screening.

5.Equipped with doublevibrators. it is able to provide a longer flowing route for screening materials and faster transmission speed with the combination of linear vibration and patented slurry recycling technologyto screening utmost fine material out of feeding slurry.

6.The installation of the patent product featuring high-quality, high open areaporosity and longlife anti-blinding abrasion resistance polyurethane screen (opening as fine as 74 microns) ensures the lowest production costs.

7. Thanks to the design of frequency conversion, it can effectively control the size of particles and more rational separation by making use of the screens.

8.corrosion and wear resistant glue spraying on the surface of screenguarantees an extended service life of the equipment and reduces the workload of equipment maintenance.

Main Operation Scope

Iron ore, ilmenite ore concentration plants

It is used to control and grade the size of concentrate. The high efficiency of the high-frequency vibrating fine screen secures salient positive enrichment among undersize material to increase the selected grade (concentrate grade can increase by 1% to 3%). As the classification becomes more efficient, the average size of the concentrate will thicken. The concentrate filtering conditions will therefore improve, reducing wet after filtration by 0.5% to 1%.

Tungsten, Tin, Tantalum, Niobium ore concentration plants

Given the fact that such ores are more brittle and big density, it is advisable to replace the spiral classifier and hydro cyclone with high-frequency vibrating fine screens or work with them so as to significantly cut down the useful materials that are too crushing and to improve the beneficiation efficiency. By doing so, the recovery rate will be enhanced by 8% to 15% and, at the same time, the processing capacity of the milling system will also see an increase of about 20 to 30% or even higher.

Raw glass material quartz sand, feldspar concentration plants

Quartz sand rod crushingproduct has wide particle size and many edges, making it more difficult to be screened. The use of high frequency vibrating fine screens ensures stable production of qualified products.

Kaolin concentration plants

It is used to control the final product size or to filter thick substances from the high gradient magnetic separator.

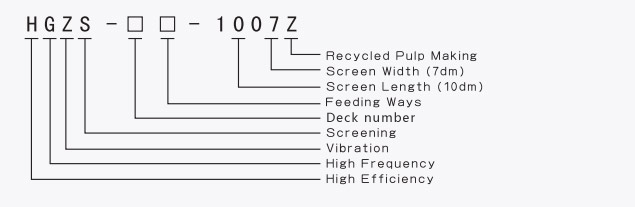

Model Composition

HGZS-□□-1007Z Product Model Composition: Model HGZS-□□-1007Z

Technical Parameters

Vibration Frequency: 1,500 RPM

Feeding Concentration:25-50% (determined by material properties)

Feeding ways:3,4,5

Opening: determine openingaccording to separation size and material property

Ambient Temperature:between-20-40℃

Vibration Motor: three-phase, 230V/400V-50HZ, customized by and imported from U.S. Martin company

Electric Vibrator Exciting Force: 0-80,000N, adjustable

Separation Concentration:≥0.054mm

Handling Capacity: 34~300 tons/hour (capacity differs from separation size)

Pitching angle:20~30degree (determined by separation size)

Noise: -80db

Lubricating Oil: special high-temperature oil

Application Effect

At present, a series of HGZS high-frequency vibrating fine screens have found wide applications in companies, both at home and abroad, and received considerable economic benefits. Such companies include Panzhihua Iron and Steel, Wuhan Iron and Steel. Shougang, Kunming Iron and steel. Baotou Steel, Tonghua Iron and Steel, Jinan Steel, Laiwu Steel, Hebei Iron and Steel, Western Mining, Fushun Hanking, Jiangxi Copper, Jiangxi tungsten industry, Nanchang Nonferrous, Daye Nonferrous, Chenzhou Mining, Zijin Mining, Yunnan Tin Group, Dachang Tin and Lomon Corporation as well as enterprises from Spain, Turkey, Chile, Peru, Russia, Kyrgyzstan, Kazakhstan, Indonesia, the Philippines, Thailand, Malaysia and other Southeast Asian countries.

Tungsten-tin: It is advisable to replace the spiral classifier and hydro cyclone with high-frequency vibrating fine screens or work with them so as to significantly reduce the useful minerals that are too crushing and to improve the beneficiation efficiency. By doing so, the recovery rate will be enhanced by 10% to 15% and, at the same time, the processing capacity of the milling system will also see an increase of about 20 to 30% or even higher.

Iron ore, ilmenite: 90% of screening substances will be controlled within 425 range by using high-frequency vibrating fine screens which can grade and control the size of the concentrate. Meanwhile, it can also increase notably the amount of iron concentrate.

|

Model |

Vibration Frequency |

Separation Size |

Production Capacity |

Motor Power |

Screening Area |

Dimensions |

Remarks |

|

HGZS-33-1007Z

|

1500

|

0.043——6.0

|

30——120

|

4.5

|

4.41

|

4045×1510×3530

|

Recycled pulp making |

|

HGZS-44-1007Z

|

1500

|

0.043——6.0

|

40——150

|

4.5

|

5.88

|

5019×1510×3889

|

|

|

HGZS-55-1007Z

|

1500

|

0.043——6.0

|

50——200

|

4.5

|

7.35

|

5640×1510×4204

|

|

|

HGZS-33-1007Z

|

1500

|

0.043——6.0

|

35——130

|

4.5

|

5.25

|

4573×1803×3560

|

|

|

HGZS-33-1207ZII

|

1500

|

0.043——6.0

|

45——150

|

4.5

|

7.9

|

5402×1803×3562

|

Two-stage recycled pulp making |

|

HGZS-44-1207Z

|

1500

|

0.043——6.0

|

45——180

|

4.5

|

7.03

|

5193×1803×3895 |

Recycled pulp making |

|

HGZS-44-1207ZII

|

1500

|

0.043——6.0

|

60——120

|

6.0

|

10.54

|

5845×1803×4015

|

Two-stage recycled pulp making |

|

HGZS-55-1207Z

|

1500

|

0.043——6.0

|

60——220

|

4.5

|

8.88

|

5813×1803×4243

|

Recycled pulp making |

|

HGZS-55-1207ZII

|

1500

|

0.043——6.0

|

80——250

|

7.2

|

13.2

|

6747×1803×5398

|

Two-stage recycled pulp making |

|

HGZS-55-Z1510Z

|

1500

|

0.043——6.0

|

170——250

|

3.92

|

15

|

8120×2177×7524

|

Recycled pulp making |

[Vibration frequency of 1,405 times/min is for domestic electric vibrator and 1,500 times/min for imported electric vibrator.]

Package product

Related Projects

Order

Contact us

Add: Non-ferrous Industry Zone, Huangjin shan Economy Development District, Huangshi City, Hubei Province, China

Tel: 0086-714-3268866

Fax: 0086-714-3268800

Http://www.xinyingtec.com

www.xinyingkeji.com

E-mail: xinyintec@163.com

907916039@qq.com

Four-Deck High Frequency Vibrating Fine Screen

Four-Deck High Frequency Vibrating Fine Screen