Tel: 400 6622 333

Detailed content

Introduction

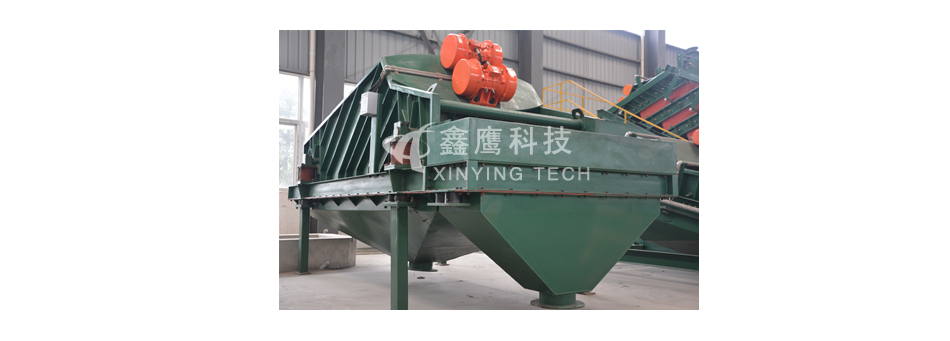

HFLS series high frequency vibrating screen is a single-deck high-frequency linear vibrating screen independently developed by our company. Based on HGZS single-deck screen and stack high frequency vibrating screen, the machine integrate field experience and market demand, further improving and optimizing the HGZS single-deck high frequency vibrating screen. The linear motion produced by the two vibrators makes the vibration trajectory more reasonable.

Features

The vibration mode is excited by vibrating motors and involves the use of a new arrangement. Since the force loading of the motor bearing is reasonable, the service life of the exciting motor is increased by two times. The use of two-way feeding method is equivalent to two screening machines at work, not only saves the occupying space, but also makes it more convenient for the replacement of the fine screens. The screening boxes of this type machine will all undergo a static and dynamic analysis, guaranteeing the strength and dynamic performance of the key parts of the screening machine. The machine calls for little maintenance, thus reducing the occurrence of machine breakdown due to human factors. And the vibration motor can be replaced quickly when the fault occurs.

Equipped with high quality polyester screens of large processing capacity, it is unparalleled in comparison with the traditional metal screens. At the same time, it is able to supply the ore through multiple channels, greatly enhancing the processing capacity per unit. In addition, its anti-clogging nature makes it possible to screen fine or even micro materials that previously cannot be or difficult to be screened.

Tungsten tin ore: It is advisable to replace the spiral classifier and hydrocyclone with high-frequency vibrating fine screens or work with them so as to significantly cut back the useful materials that are too crushing and to improve the separation efficiency. By doing so, the recovery rate will be enhanced by 10% to 15% and, at the same time, the processing capacity of the grinding system will also see an increase of about 20 to 30% or even higher. Iron ore, ilmenite: The high-frequency fine screen is to control and classify the size of the concentrate to remove materials cling on coarse. The production capacity of the same mill can increase the concentrate grade by 1-3% while reducing the moisture content of the concentrate by 0.5-1%

The use of HFLs series high-frequency linear vibrating screen rather than the vibrating screen can improve the screening efficiency by more than 20%, and the processing capacity of the grinding mill is improved by more than 10%.

Specification & Model

|

Model |

Separation Size |

Motor Power |

Screening Area |

Handling Capacity |

Weight |

Remarks |

|

HFLS-11-1207Z‖

|

0.054-2

|

2×1.2

|

2.625

|

10-50

|

2180

|

One feeding

|

|

HFLS-12-1207Z

|

0.054-2

|

2×1.2

|

3.5

|

20-100

|

3550

|

Tow feeding

|

|

HFLS-11-1407Z‖

|

0.054-2

|

2×1.5

|

3.045

|

12-60

|

2910

|

One feeding

|

|

HFLS-12-1407Z |

0.054-2

|

2×1.5

|

4.06

|

18-90

|

3660

|

Tow feeding

|

|

HFLS-12-1407Z‖

|

0.054-2

|

2×1.5

|

6.09

|

24-120

|

4750

|

Tow feeding

|

|

HFLS-11-1807Z‖

|

0.054-2

|

2×1.5

|

3.885

|

15-80

|

3800

|

One feeding

|

|

HFLS-12-1807Z

|

0.054-2

|

2×1.94

|

5.18

|

25-120

|

4800

|

Tow feeding

|

|

HFLS-12-1807Z‖

|

0.054-2

|

2×1.94

|

7.77

|

30-150

|

5750

|

Tow feeding

|

|

HFLS-11-2407Z‖

|

0.054-2

|

2×2.2

|

5.145

|

20-100

|

4800

|

One feeding

|

|

HFLS-12-2407Z

|

0.054-2

|

2×2.2

|

6.86

|

30-150

|

5850

|

Tow feeding

|

|

HFLS-12-2407Z‖

|

0.054-2

|

2×3.0

|

10.29

|

20-180

|

7300

|

Tow feeding

|

Package product

Related Projects

Order

Contact us

Add: Non-ferrous Industry Zone, Huangjin shan Economy Development District, Huangshi City, Hubei Province, China

Tel: 0086-714-3268866

Fax: 0086-714-3268800

Http://www.xinyingtec.com

www.xinyingkeji.com

E-mail: xinyintec@163.com

907916039@qq.com

HFLS Series High Frequency Linear Vibrating Fine Screen

HFLS Series High Frequency Linear Vibrating Fine Screen